|

|

|

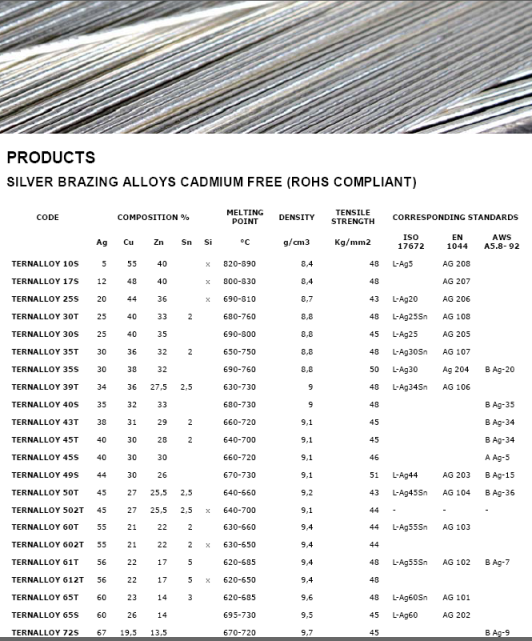

Brazing alloys

Why Brazing?

Brazing has been around for 1000s of years. Brazed joints have been used in plumbing, air-conditioning, heating, electronics and numerous other applications for a very long time. A brazed joint will last a lifetime, other materials such as plastic have not been around long enough to make the same claims.

- Brazing provides High Strength Joints. With the proper joint design and correct selection of brazing materials, brazed joints will be stronger than the base materials being joined.

- Only brazing can truly insure leak free joints in critical applications such as flammable gases or medical gas installations. Therefore many norms require that such critical installations be brazed.

- Brazing is Hygienic. Tests have shown that copper tubes that are brazed contain much lower concentrations of bacteria, which means more safety for you and your family.

- Brazing can be used on Dissimilar Metals and Materials. With brazing materials and processes practically all metals can be joined with each other. Also, nonmetals like glass or ceramics can be joined with brazing processes. The ability to join different materials easily makes the design, development and production of new products possible.

- Brazing is a low cost process that requires very low investment in equipment.

- Brazing is excellent for high volume production because the use of pastes, rings and wire allows for excellent automation possibilities. .

- Brazing is Easy. It literally takes less than one hour to teach someone how to perform basic brazing operations. The ease of brazing should allow a company to be flexible in their production, and the company should have little problem finding brazers. Eutectic’s range of products makes brazing easy by creating products that allow for a wide range of error by the brazer.

|

|

| VAT 24% not included € 0.50 |

|

|

|

|

|

|  |

|

|

| VAT 24% not included € 4.50 |

|

|

|

|

|

|  |

|

|

| VAT 24% not included € 15.00 |

|

|

|

|

|

|  |

|

|

| VAT 24% not included € 11.50 |

|

|

|

|

|

|  |

|

|

| VAT 24% not included € 33.00 |

|

|

|

|

|

|  |

|

|

| VAT 24% not included € 15.90 |

|

|

|

|

|

|

|

|

|

| Members' login |

|

|

Mailing list for Tepse news!

Wish to receive our product news and other?

Please enter your e-mail address here.

|

|

|